Methods of Dealing with Tank Floor Corrosion in Fajr jam Refinery

In this case, the reservoir that is closer to the anodic bed (TK-8101C reservoir is closer to the anodized bed of the northwest side than other reservoirs) will have a more negative potential than other reservoirs. At present, the failure of some insulating flanges and the existence of an extensive earth network have caused the electrical connection of all tanks with each other and therefore, the use of electrical resistance in the path of drain cables through the current control box (CCB) has no effect on the disrtibution of cathodic protection potential and only increases the power consumption of the system. In the case, the reservoir that is closer to the anodic bed (TK-8101C reservoirs is closer to the anodized bed of the northwest side than other reservoirs) will have a more negative potential than other reservoirs.Considering that the potential of the TK-8101C tank should not be too negative (Over protection mode), this has caused the Under protection mode in the next tanks.

The following solutions were investigated to deal with tank floor corrosion.

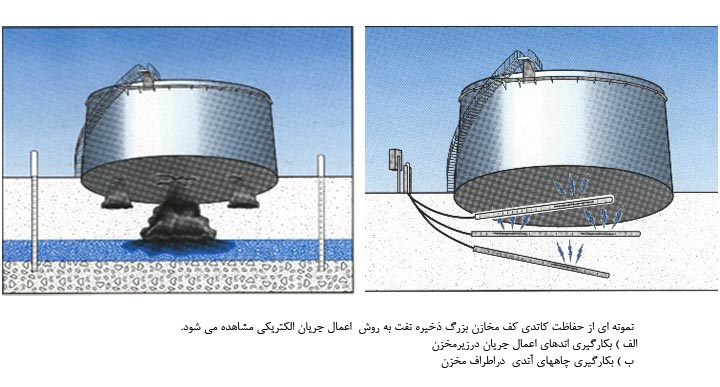

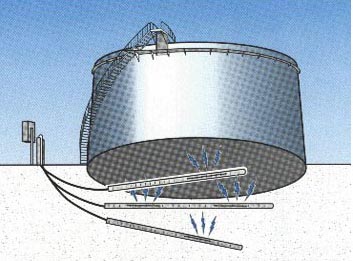

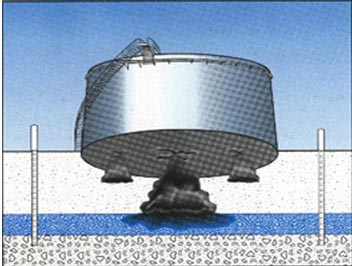

- Application of cathodic protection system

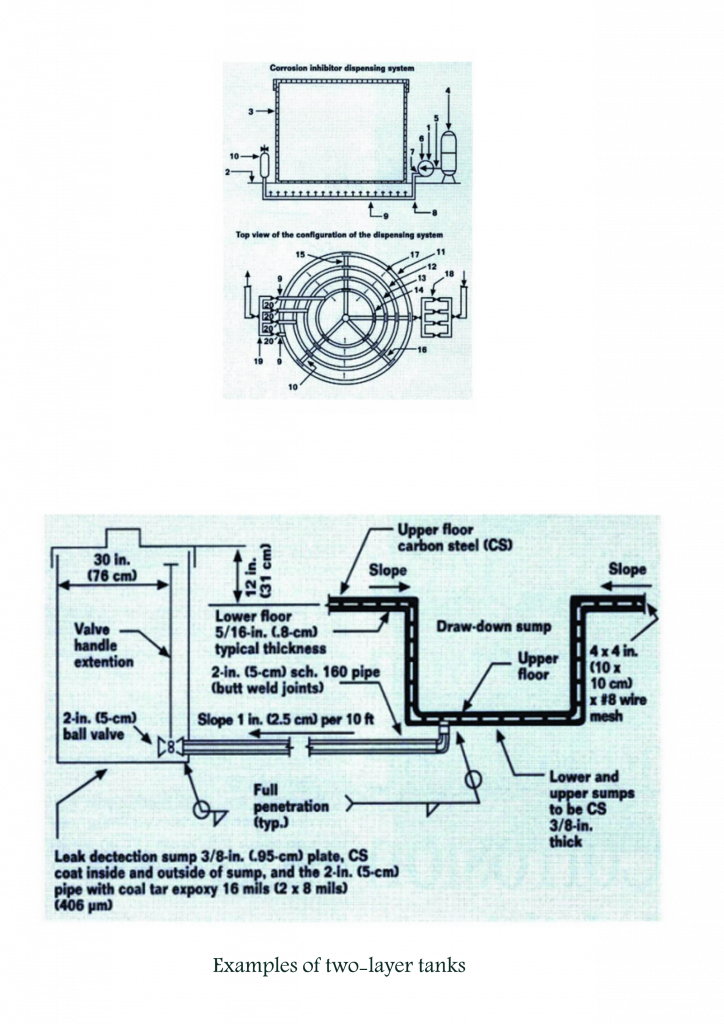

- Application of vapor phase corrosion inhibitors

- Simultaneous use of cathodic protection and vapor phase corrosion inhibitors

Experimental results show that The cathodic protection system alone is not able to protect the bottom of the tanks. Large oil tanks with cathodic protection systems have leaked on several occasions.This was while the bottom of the reservoirs had the potential of cathodic protection.

This has caused a lot of damage to the environment and severe groundwater pollution. In the project, the floor corrosion protection system of large gaseous liquids storage tanks was designed.